Profile Sheets

Roofing sheets are manufactured from a range of materials, each known for their varying properties and applications on different types of roofs. Choosing the right roof sheet can increase the longevity and durability of your roof. Different types of roof sheets come with their own unique set of pros and cons. Each type caters to different needs. Your roof is only as strong as the materials that it comprises. The level of protection that your roof receives ultimately depends on the clever combination of various materials that work together to provide maximum performance. Whether the roof is for your garage, shed or a different building entirely, roofing sheets are vital for protecting your roof from harsh weather.

They act as a physical barrier, shielding the more vulnerable underlying components from high-winds, torrential downpours, snow and hail. Plus, thanks to various technological advancements, these sheets boast an incredible range of features and functions and are available in all manner of sizes. The only thing you need to know is which roofing sheet is best suited to the building you’re working on.

AC roofing sheets

Asbestos cement (AC) is a material which contains 15 per cent of asbestos fibres evenly distributed and pressed with cement. They are manufactured in large sizes, with corrugation or with Trafford to get good strength with less thickness.

FRP/ GRP roofing sheets

Fiberglass profiles are a cost-effective alternative to traditional materials such as concrete, steel, aluminum and timber. Whereas these materials have only one primary strength, GRP combines several advantages. This makes fiberglass ideal for the sustainable construction of the future. It gives you the same great strength as steel, but at only a quarter of the density. It is also possible to make weight savings in comparison with aluminum, as the density is 30 % lower. They are resistant to aggressive chemicals, liquids and alkalis. This makes them ideal for wastewater treatment plants, swimming pools, cooling towers and construction, where there is a risk of corrosion. These sheets are widely used for roofing applications in architectural roofing, skylights, transparent acoustic barriers, covered walkways etc.

Corrugated roofing sheets

Corrugated roofing is highly durable and it is because of its shape. These sheets require the support strips to stabilize the material since the screws for fastening do go through the peak of the ribs. The curvature of the ribs and valleys prevents the screws from sealing adequately in the valleys. Because of the special corrugated shape, flimsy and lightweight metals like aluminum can also be equipped to undergo decades of weather beating. The most popular corrugated sheet is a galvanized steel sheet, which is used mostly as the base material. These roofing sheets are ideally used for protecting garages, porches and sheds.

PVC roofing sheets

PVC is resistant to weathering, chemical rotting, corrosion, shock and abrasion. It is therefore the preferred choice for many different long-life and outdoor products. In fact, medium and long-term applications account for some 85 percent of PVC production in the building and construction sector.PVC has been a popular material for construction applications for decades due to its physical and technical properties which provide excellent cost-performance advantages. As a material it is very competitive in terms of price, this value is also enhanced by the properties such as its durability, lifespan and low maintenance. PVC’s abrasion resistance, light weight, good mechanical strength and toughness are key technical advantages for its use in building and construction applications. PVC is resistant to weathering, chemical rotting, corrosion, shock and abrasion.

GI roofing sheets

The GI coating has a unique metallurgical structure and gives protection against any abrasion, or mechanical damage that may occur during transportation, erection and service. GI roofing sheets are fitting in providing automatic protection to any damaged area of the sheet. The sheets give them cathode or sacrificial protection to any small area damaged during transportation. Thus the entire length of the sheets is protected by the coating.

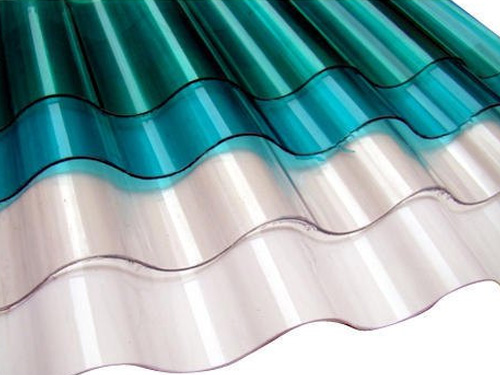

Polycarbonate roofing sheets

Polycarbonate roofing sheets are available in a variety of qualities and thicknesses. They are much lighter in weight, yet durable, and resistant to breakage and cracks. They can be easily handled and can be fixed with the help of screws and support rods, or can be easily welded. Also, these sheets can be easily cut with the help of sharp-edged scissors and circular saws without the need for any additional tools and machinery. Polycarbonate roofing sheets being so strong and flexible helps the structures it is used to be more creatively designed. One of the most beneficial features of polycarbonate is that it lets in maximum sunlight while keeping out the harmful UV radiation. Therefore, it is the ideal choice when you want maximum light to come in without being harmful. These sheets are widely used in industrial and large-scale commercial buildings.